An Interview* with Constance Adams Architect for the TransHab Inflatable Space Station Module *

via email

Lightweight yet providing large and useful volumes, such inflatable structures clearly offer great advantages for space stations and also for building bases on the Moon and Mars. Many space advocates recognized, as well, that TransHab type modules could allow for quick construction of orbital space hotels and other facilities to house large numbers of people. Unfortunately, the big budget shortfalls and delays in the ISS project, along with various political machinations, led Congress in 2000 to restrict NASA from spending any money on TransHab beyond the design studies. Even worse budgetary problems since then led to the indefinite delay of the installation of even the default hardshelled habitation module. See this Houston Press article from August 2000 for an interesting history of the project and the role Ms. Adams played in it. This report by student at Embry-Riddle University provides a good summary of the technical aspects of TransHab. (More links.) I managed to find Ms. Adams via the Net and she generously agreed to answer some email questions about TransHab. We also discussed the general challenges of designing structures for space and how an architect applies her skills to aerospace projects. I've assembled the interaction into an interview format here.

Many trade studies were then performed to determine which choice would better suit the ISS’ immediate needs and current budgetary constraints. In terms of long-term and operational costs and needs, there was no question that the ISS-TransHab module would save the program tens or hundreds of millions of dollars over the first decade, and would give the overall Station several assets that it does not and could not otherwise have. These included a safe-haven shelter for solar storms, on-orbit water recycling capability, more than double its current total stowage volume, and the ability to test new exploration-class technologies like a human centrifuge, advanced medical facilities and lighting as well as the inflatable shell and orbital-debris shielding for which TransHab has become famous. NASA’s Human Exploration and Development of Space (HEDS) roadmap defines all of these technologies as essential developments for any long-duration human expeditions beyond earth orbit, such as a return to the Moon or the exploration of Mars. However, you are right in understanding that the discovery in early 2001 of a $4.8B shortfall in the ISS budget has had wide-ranging effects in America’s overall space program, almost all of them very damaging. One of the first things to be cut from the program was the habitation module and supporting elements of the ISS, including the Crew Return Vehicle which would be necessary to allow the crew to grow from 3 to 7. Currently there are no NASA efforts I know of to develop any space inflatables, but this does not rule out the possibility of recovering this program if and when the funding scenario changes or another mission is found for similar vehicles. I am myself working on design ideas and scenarios for the next generation spacecraft, including the Orbital Space Plane, including a new concept for heat-shielding to reduce the risk of recurring damage like the Columbia scenario..

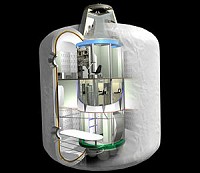

Both of the solutions involve patents filed by the TransHab structures team, so my ability to discuss them is limited. However, I can say that the strength of the shell is dependent on a specialized weaving pattern that permits straps of woven Kevlar to withstand remarkable amounts of stress. The final TransHab test unit withstood over four atmospheres of pressure differential (54psi) before the test was stopped; it has to date never been made to fail under similar tests. The ability of TransHab to maintain its shape and support equipment attachment is due to its endoskeletal structure. In other words, like us it has a hard internal structure that helps it keep its shape and to which its systems equipment is attached, allowing its outer shell to do its job without interference. This hard core structure is made of light composite elements and allows TransHab to be secured in a shuttle’s payload bay or on other launch platforms in a deflated, cylindrical form prior to its inflation and assembly on orbit. . HS: When I see photos of the interior of Mir it reminds me of my days doing research at particle accelerator labs. We would spend endless hours in the experiment control rooms that were packed with electronics racks, cables streaming everywhere, piles of manuals laying all over the place, and loud cooling fans running constantly. Not great working conditions! However, at least we got to go home occasionally. Living in that kind of environment 24 hours a day for several months could become a nightmare. ISS was supposed to be different than Mir, but recently I read that it has started to become just as cluttered as Mir with equipment scattered all about, walls covered with stuff attached to Velcro, and so forth. On top of this the noise levels are much higher than expected. Do you feel a bit of the "I told you so?" when you hear such descriptions of the ISS? Besides the fact that Transhab was simply more voluminous, what was there about its layout that would have encouraged a more orderly, productive, and pleasing environment to live and work in?

In response to your question let me suggest without any kind of criticism, that very few of the things you say about living and working conditions on ISS were a surprise to the people who have been working on crew systems and human factors for years. Remember that the basic US ISS architecture dates to the mid-80s (and the Russian modules date to the Salyut stations in the mid-70s), so by the time the first modules were launched in 1999 there had been plenty of time to anticipate issues. The problem the human-systems folks faced then were the same ones they have always faced: the first and last decisions are made by Engineering, and it’s generally understood that clutter and noise are pretty minor problems compared with the hard vacuum and 500-degree temperature fluctuations of outer space. They knew these things were coming at them, and as hard as they tried to get attention to the problems, in many cases there just wasn’t anywhere for the program to budge to resolve them. This is why TransHab was so exhilarating for most of us: it was new, and we had an opportunity to make all its rules while implementing lessons we had learned from previous designs and programs. One of the most radical changes was in process: there were Architects at the core of the design from the beginning. Rather than approaching TransHab’s design as first a structural problem, then a systems problem, then an “outfitting” problem, as has always been the process before now, TransHab had experts on its design team that agreed to look at all those areas simultaneously. One of the arguments we used to keep that focus was that, in the world of human spacecraft, our end product would be worthless if it did not.

Losing that team is the thing I regret the most about the end of that project, and it would be a terrible shame if anyone contemplating the continued development of an inflatable module did not at least try their best to reassemble those very people for the next level of work. In terms of intellectual capital, the TransHab team was built by the money the American people put into TransHab, and was tested and approved by important representatives of the only other American generation to have designed, built and flown any vehicle meant to support humans in outer space. I think of many books that have recently been published, including Chris Kraft’s autobiography Flight and Gene Kranz’s Failure is not an Option, and need go no further to support this idea. One of the things Kraft keeps emphasizing in his book is how much more complex a spacecraft is than any other kind of vehicle, and how much more difficult it is to develop one than any of them had imagined. I can attest to that. It’s one of the truest things I ever read. Many talented, smart, hardworking and experienced people dream of working on space hardware; but until you’ve done it, I don’t know that it is possible to understand just how much harder it is to do. What worries me is the thought that this country might be in danger of losing the greatest technical capability it has, if it waits too long to start committing itself to building the next generation of spacecraft, because the know-how developed by trial and fire in the 60’s and 70s is almost gone and very few people of the current generation have had the opportunity to learn from them how to do what they did. The TransHab team became, almost by accident, one of the very few seedlings planted by those great old trees.

HS: One common view of living in space, for example, is that it would be just like living in a submarine - dark, dank, and claustrophobic. With Transhab we see in fact that a space habitat can have large open areas even at this early stage in space development. Dealing with a one atmosphere pressure difference is a lot easier than dealing with many! Adams: Well, or even less: although ISS is pressurized to sea-level at 14.7 psi, the Space Shuttle is usually only pressurized at 10.2 psi, and Russian space stations even lower, at a range between 4 and 8 psi. In its vacuum test, the TransHab shell had assumed its full shape by the time it had only 0.5 psi! We were amazed. Still: I’m not sure what the relationship between the first and second part of the question is, though; the pressure environment isn’t the only thing driving the architectures in question. Well, inflatables are not likely to be very useful under water if that’s what you mean… although I remember hearing there was some talk of using a TransHab type inflatable as a portable decompression chamber for diving teams. That’s not the same thing, but it would permit rapidly-rising divers to be placed into a high-pressure environment inside the inflatable as soon as they are back on deck, I think. In any event, if your point is that inflatables are mainly useful when the desired pressure differential from inside to outside is negative (i.e., when the pressure inside is higher than outside), then you are of course correct. Something like the opposite of an inflatable is necessary under water; and maybe we have been sort of fooled by the accident of cylinders being used both for spacestations and for submarines, into thinking of them as similar conditions. This is an interesting point of departure for a whole new level of thought about paradigmatic forms for different environment.

Video was used, for example, to allow the cosmonauts to control remote docking of the Progress resupply capsule to Mir; and because of various possible glitches like EMP hits or other fields that can interrupt transmission of signals, or maybe just failure of a camera or an antenna, the big accident of July 1997 happened because the commander on Mir was flying blind. He couldn’t actually see the Progress because he had no window near his controls, and the video was illegible. Many near-accidents in our own space program have been averted by the intervention of skilled pilots using their windows and whatever controls they had available to find solutions when automated systems broke down. It’s funny that, despite the repeated lessons in human spaceflight that continue to point to the value of the trained human operator with direct visual contact and mechanical control, somehow the public continues to subscribe to the “Spam-in-a-can” theory of astronautics. Think of “Apollo 13”: those guys would never have made it home without some windows through which to use visible bodies as guides for their burns. Although I started working in this program as an architect and human factors expert who insisted on the importance of windows, my experience with BIO-Plex and TransHab taught me to understand what the engineers fret about when they are required to include one in their vehicle. The level of risk that is latent in that product is much higher than if no window were present. BUT: in the long-term use of the spacecraft to perform its mission, it seems to have been proven by history that the best and most reliable redundant emergency system you can have is a human who knows how to make it fly and has a window to allow failproof visual contact. It’s a tough balance. I think that a combination of the two will ultimately be the best balance for long-duration flights.

HS: Sunlight would have great positive psychological benefits. I can envision, for example, a large "sun room" to relax where one could select filtering of the piped in sunlight to produce, say, a bright day at the beach or a midsummer sunset. . Adams: Great idea! HS: For space tourism the visitors would obviously prefer such an airy, well lit "space hotel" to the Mir or even ISS environment, which bear a resemblance more to the cramp service tunnels running underneath a hotel! Adams: I disagree. Beaches, we have here on Earth. What tourists cannot get on the Earth is a view of outer space: the stars, our Moon, the beautiful Earth. Too much sunlight would drown out that view, just as streetlights generate too much light pollution down here for stargazing in many regions. As for open space, a short visit in space is typically characterized by an initial phase of space adaptive syndrome (SAS) which can be really disabling for some days, followed by a real difficulty learning to use their bodies without gravity. Just getting dressed in the morning can take an hour of terrific effort unless you are in a cozy corner against which you can prop your limbs. So, while some large volumes might be fun, the space tourist’s needs in terms of volume, form and function are not necessarily compatible with the needs of a long-duration crew who are working 12 hours a day on orbit for months at a time.

HS: I believe that Bigelow Aerospace is planning to use an inflatable structure for its space tourist hotel. Are you familiar with their plans or any other commercial project with inflatable structures? Adams: I think Bigelow has disbanded that team. But even if not, it’s not really appropriate for me to discuss their project. [May.31.03 - I've been informed that Bigelow is still working actively on inflatables. See the note below.]

HS: I was wondering if you had some culture shock, or at least a lot of arguments, when working on a project like the Transhab with, forgive the stereotype, hard nosed engineers who just want to "build something that gets the job done"? Adams: Architects aren’t dilettantes; we all want to get the job done, and unlike many engineers, a project’s Architect often carries sole and personal legal liability for every building they stamp. So getting it done and done right is a common goal. Actually, during the times when I have been busiest in the space program I found myself participating on engineering project teams that were vastly more cooperative than most architecture groups, and with less ego flying around. The most important operative aspect of the NASA work environment is the emphasis on the idea that “no question is a stupid question.” That was never true in any other environment, social or professional, I have ever been in; yet if something as insanely challenging as a spacecraft is going to be built and fly safely, it really is a fundamental ingredient of the workplace. The main challenge is always in teaching my engineer colleagues how an Architect works, and how we can help them, not compete with them. Typically, engineers are trained to work in a linear fashion, whereas architects work in a sort of holistic or concentric fashion with the project progressing from the center of the tree to its bark. Getting these processes to work together means helping each of the people following a radial process to understand the integrative function the architect performs on the team. But once that hurdle is past, it’s really wonderful to see how well a team can work! I am now beginning to try to explain this process to Architects, and it’s harder than you might think. Anyway, I am working on a book right now about NASA and how it really is the last holdout in our civilization of the culture of Great Projects, a place where everyone works because they believe in the goal, in the end-product, and not for some personal gain. It is the best kind of culture-shock I can think of, to come into that environment after the empty competitiveness of private industry. One of the things I will remember best was the feeling I had the first time I went back to New York to visit friends and old colleagues after starting work at the Johnson Space Center. Where I expected to feel like the country bumpkin returning to the Big City from swampy Houston, instead there was this interesting reversal. Even when talking with or about old friends who were working in the coolest offices or for the most interesting clients, I realized that what they were doing was beautiful and publishable and expensive—but it wouldn’t likely matter to their great-grandchildren, and it probably didn’t even feed their soul today. For a big change, I felt that I was the fortunate one because every stupid little thing I did at work made some kind of contribution to what I believe will be the future of humankind. Hopefully, for the better! Apparently this kind of value doesn’t matter to most people; but to those of us who do need to feel that our work has a greater significance, there is no greater pleasure than working in a program like the Space program. HS: I certainly understand your enthusiasm and passion for such work. Thanks very much, Constance. Best of luck with your new projects. The

members section at

SpaceArchitect.org

includes a brief resume of Ms. Adams. SpaceArchitect.org

provides an extensive reference list of papers and articles Notes/Feedback Mar.21.04. Constance now has two other web sites: synthesis international USA and the MOTHERSHIP Jan.16.04. Constance offers a lot of excellent suggestions for NASA in this essay: It Doesn't Take a Rocket Scientist by Constance Adams - Popular Science - Feb.04 issue. The article also included sketches of the TransHab module as it progressed through the design process: It Doesn't Take a Rocket Scientist - Transhab development sketches June.3.03. I've been informed my Tony Rusi, a former employee of Bigelow Aerospace (includes links to articles about Bigelow), that the company is very actively working on inflatable structures: "They have not disbanded, but they are a very small organization. In fact, they are in the process of full scale hydrostatic tests of a Vectran edge-sewn and arc-sewn narrow webbing pressure shell." ... ..."The cheap

revolutionary manufacturing process Bigelow uses could make a pressure

shell of almost any size for future space colonies, hotels, and ultra-large

compactable propellant tanks. Others have used weaving, braiding, fiber

placement, and filament winding machines to make flexible pressure vessels.

All these other methods require expensive new design, for single purpose

machines, that will take millions of dollars and years to set up."

|

||||||||||||||||||||||||||

|

||||||||||||||||||||||||||