The Rocket Company Chapter 4: Build Big, Build Many, or Use it Again

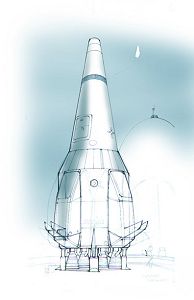

The vehicle concept which Arthur Schnitt had developed was based on using very simple technologies to build large vehicles that had rather low efficiencies. Whereas the Saturn V placed approximately one pound in orbit for every 22 pounds of vehicle lift-off weight, Schnitt's design placed one pound in orbit for every 40 to 50 pounds of vehicle lift-off weight. Hence the sobriquet "Big Dumb Booster." Even if "big and dumb," it would - at least theoretically - be much cheaper to build and fly. Schnitt's booster, and virtually all later attempts to build on his concept, employed simple but heavy high-pressure propellant tanks which were filled with fuel or oxidizer, and then pressurized using an inert gas, main tank injection, or by heating the propellants to raise their vapor pressure. The high pressure forced the propellants into the engines. This eliminated the need for costly and troublesome turbopumps to do the forcing. The engines likewise were of simple design, using relatively few parts, and were also relatively low cost to construct. In the 1990s, Beal Aerospace tried such an approach but with lighter weight composite tanks. Even though they built and successfully test-fired an 800,000-pound thrust rocket engine, they withdrew from the field before flying their vehicle, at least in part for political reasons, with a public statement by their CEO to the effect that competing with NASA was simply not possible. The next approach, using the "refrigerator theory," involved selecting an existing vehicle such as the Delta, or perhaps one of the Russian or Chinese boosters, buying a license to produce it, redesigning it for manufacturability, and then putting it into production using, not the overpriced engineering and manufacturing methodologies and ideologies of the defense contractors, but rather standard industrial techniques such as were employed by the Chinese in their refrigerator factory. To a certain extent, the Chinese and the Russians could be said to have used this approach. Their designs were clearly not low-tech, but they were, as near as anyone could tell, a lot cheaper to produce than the comparable U.S., European, or Japanese boosters. The concept was simple: put a launch vehicle into mass production on a world-class, lean manufacturing production line, and see if the cost didn't fall by a factor of ten or more. The third approach was intuitively very appealing, if not well supported by industry experience to date. It was based on what everybody knows about airplanes: they are highly sophisticated machines built by well-established and profitable aerospace companies, with levels of reliability and efficiency that make air transportation the safest and most economical means of transporting people over long distances. And while the aircraft themselves are not cheap - prices for commercial airliners range up into the hundreds of millions - they are at least affordable enough to be operated by private airlines and owners the world over. If you could do that with something as sophisticated as a Boeing 747, why couldn't you build a rocket that did the same? Since this approach was based largely on "gut-feel," it was sometimes taken to the logical extreme that it would most likely be successful if the reusable spacecraft looked like an airplane, with wings and wheels - if it looked like an airplane, it should cost like an airplane, the reasoning went. The monumental failure of the Space Shuttle to achieve not only its original performance targets, but also any cost reduction at all over the expendable vehicles that it was supposed to replace, had not dampened the widespread enthusiasm for this approach. Since the mid-1980's, NASA had been funding one airplane-look-alike design study after another, and was even now preparing to let final bids on their latest concept, boldly proclaiming that this time it really would replace the Shuttle and dramatically lower the cost of space transportation. Forsyth asked Tom where he thought the solution lay. Tom leaned back, thought for a bit and said, "I think it's in the fully reusable vehicle that functions like an airplane, although I don't think it will look like an airplane." He went on to elaborate, however, that the problem of analyzing the feasibility of such a vehicle is much more difficult, compared to the problem of analyzing a big dumb booster design or a concept for an efficiently mass-produced existing booster. "Well," said Forsyth, "why don't you put together three design teams - one to come up with a big dumb booster-type vehicle, and take a look at what we could do to reduce space transportation costs with that. Put a second team together - ignoring for the moment the cost of a license for the technology - and come up with a good estimate of how much costs could be reduced by using commercial best practices manufacturing. Finally, without getting bogged down in endless design trades and architecture studies, try to pin down the general parameters for the economics of a fully reusable, airplane-like vehicle, again without wringing out all of the particular technical issues and solutions - at least for the time being. With that kind of information in hand, maybe we'll be able to see more clearly how a market could be created for whatever looks to be the most feasible approach." Tom allowed as how he thought they could get something useful together in three or four weeks that would lay out the general parameters for the different approaches. He got to work right away, forming from the ranks of his ever-expanding staff three teams, one for each of the approaches. In performing a vehicle concept study it was important to use parametric values for such things as weight, cost, and performance estimates in order to save time. Besides, you weren't going to be designing the complete vehicle anyway. It was also very important to use numbers that came from systems that had actually been built, in order to keep the designs honest. In Tom's experience, the wildest "flights of fancy" - improbable or often impossible designs - came from engineering teams that got too far away from their own experience. They would leave behind the realm of hardware that had actually been found to work, and even what had already been found not to work, and start making it up as they went along. Or, just as bad, they started using other flights of fancy as their starting point. No doubt progress is at times made by geniuses who leapfrog over the conventional wisdom, but genius is where you find it. It's not usually the prime mover in a successful design program; engineers are most likely to succeed if they incrementally build on known technique. After all, the graphical user interface was created by a genius at Xerox, but it was Steve Jobs who built something useful out of that creation. Back in 1996, a man named John Whitehead wrote a paper (AIAA96-3108) in which he showed that the weights of typical launch vehicle stages had not changed substantially over time. If tank weights have not improved in fifty years, it's best not to assume you can dramatically beat history. Whitehead also noted that tank weight as a function of propellant volume was essentially constant over a wide range of tank sizes, from a few tens of thousands of pounds to well over a million pounds. He highlighted the fact that the weight of a tank capable of holding a given quantity of propellant was directly proportional to the propellant density, because the tank weight was almost completely dependent on the volume of the propellants. Whitehead also addressed the other major weight contributor in a typical stage, the rocket engines. For dense propellant combinations such as LOX/kerosene, the engine typically weighs 1% of the thrust (for a "thrust-to-weight ratio" or T/W of 100); for lower density propellants such as LOX/LH2, the figure is in the neighborhood of 2% (T/W of 50). A third but smaller contributor is the propellant pressurization system weight. This system provides the gas pressure that is used to force the propellants through the piping of the feed system and into to the turbopumps which feed the engines. Finally, there is the weight of the residual propellants that remain in the tanks or the feed lines and are unused by the engines. The remaining structural elements in the stage, the engine thrust structure, which transmits the thrust of the engines to the loaded propellant tanks, and the payload or upper stage support structures were not considered by Whitehead because these tend to be much more design-specific. The purpose of his paper had been simply to point out which structural elements of a typical launch vehicle stage were more or less mature in terms of achievable weights, and which were likely to benefit from better engineering in order to reduce their weights. Whitehead's main concern was the problem of single-stage vehicles. For a single-stage vehicle, the rocket equation - MR=e(Velocity/ISP*32.2) - tells you, for a given engine ISP (i.e. jet exhaust speed divided by acceleration due to gravity) and a total desired velocity change, what fraction of the initial stage mass would achieve that velocity change. The mass ratio, MR, is the ratio of the initial mass of the stage to the final mass after all of the propellants necessary to attain your desired velocity change have been burned. If that desired velocity change is equal to that required to go from zero at your launch point to orbital velocity, then it will tell you how much of that initial mass will reach orbit. Whitehead, by characterizing tank, engine, and propellant feed system weights as percentages of the total final or empty weight of the stage, provided a fairly accurate means of estimating how much weight could be allocated to the other structural and vehicle components, and more importantly, how much payload could be included. In other words, if you know the percentage of the final weight that must be allocated to the tanks, engine, and pressurization system, then you can determine how much is left for the other vehicle systems and the payload. Considering the parametrics of a pressure-fed design, three factors must be considered that contribute to lower performance as compared to a turbopump-fed stage. The first is the greater weight of tanks strong enough to support the higher internal pressure needed to force the propellants all the way to the combustion chamber. Secondly, because this pressure is typically 5-10 times higher than the internal pressure required for a pump-fed stage, the weight of the gas used to pressurize the tank is also proportionately greater. Lastly, the engine specific impulse (ISP) is also typically lower for a pressure-fed stage because the engine chamber pressure tends to optimize at a lower value when the increased weight of the pressurization system and tanks is considered. The higher the tank pressure, the greater the weight of the tank and the pressurization system, which drives the design toward a low-pressure engine. Thus by eliminating the turbopumps - which are complex and expensive both to develop and to produce - the designer accepts higher weights and generally lower specific impulse. Because of the high tank weight, pressure-fed vehicles have typically utilized dense propellants and lightweight pressurizing gases. For a typical pump-fed stage the tanks weigh approximately one percent of the weight of the propellants (for propellants with a density about the same as water). If the pressure in the tanks is increased by a factor of ten, one would expect the tanks to grow to about ten percent the weight of the propellants. To minimize this weight growth, high strength-to-weight materials are typically employed. It would seem logical, therefore, to use composites with their very high strength-to-weight ratios. However, for a stage with a propellant capacity of a million pounds (again, assuming the density approximates that of water) a tank sixteen feet in diameter would be eighty feet long. This presents some serious manufacturing difficulties in laying up and curing the tanks; the highest strength composites require autoclave curing - and that would take a very large autoclave. In the past, high strength steels like maraging steel, which has very good strength at cryogenic temperatures, or high strength, low-alloy steels such as HY-180 have been suggested. Both of these materials have been used for solid rocket motor cases. In many ways, a pressure-fed vehicle is similar to a solid rocket. In a solid rocket all of the propellants are contained in the combustion chamber where, during operation, the pressure is typically in the range of 500-1,000 psi. To withstand these high pressures, composite-wound cases have been used in many missiles and rocket boosters. However, for the extremely high performance upper stages - such as the Thiokol Star 48 motor, the case is a thin-walled titanium shell weighing only about 3% of the weight of the propellant contained. The solid propellants used in Star 48 actually have a density about 1.6 times that of water. Thus, it is theoretically possible to build a high-performance, thin-walled titanium tank that weighs approximately 5% of the weight of its contents, if those contents have a density about the same as water. The Pressure-Fed Concept The concept which the first team came up with was a two-stage launch vehicle. Considering the low performance of pressure-feds, three stages might provide higher performance, but Tom reasoned that, for the purposes of estimating costs, two stages would be close enough. The costs for a vehicle with two stages were not likely to be substantially higher than those for a three-stage vehicle, because the higher performance of a three-stage vehicle would have to be weighed against the cost of the additional stage. The first stage had a gross weight of 900,000 pounds and was constructed of high strength rolled AerMet 100 with a yield strength of 261 KSI, an ultimate strength of 300 KSI, and an elongation of 10 percent before rupture. AerMet 100 is a recent development, a new martensitic super-alloy that is stronger and less expensive than other super-alloys such as Inconel 718. HY180 was also a possibility; it is a high strength low-alloy steel with good ductility and good weldability. It had been proposed for use in the original "big dumb booster" studies. The first stage was actually one pressure vessel divided into two tanks by a common bulkhead. The reason for this approach was twofold. First, the common bulkhead - the dividing wall between the oxidizer and the fuel tanks - could be constructed from thinner material because it would be subjected to lower stresses than the other portions of the tanks; it would only need to withstand the pressure differential between the two propellants. An interesting property of materials, which pressure vessel designers always have to keep in mind, is that it is important not only to use a strong material, but also a material which resists the formation of cracks. After all, glass is as strong as steel, but nobody would like to sit next to a glass tank with 3,000 psi compressed gas inside. If such a tank started to crack, you would be sitting next to a bomb. For metal tanks, it turns out that the material is toughest - that is, the most resistant to tearing - at a particular thickness. Very thin materials are very easily torn; aluminum foil for example, is usually torn by hand when you need a piece. An aluminum pop can is rather less prone to tearing, and a 1/8th-inch thick aluminum plate much less so, and not just in proportion to the greater thickness. After all, even the soft unalloyed aluminum used for foil has a yield strength of about 10,000 psi, and with a thickness of two or three thousandths of an inch, it would seem that a force of 30 or 40 pounds would be necessary to press your finger through a sheet of it. But, as we have all experienced, it is quite easy to tear once you get it started! The upper stage would weigh approximately one hundred thousand pounds and consist of an aluminum vessel over-wrapped with S-glass. The majority of the aluminum was subsequently removed by dissolving it with sodium hydroxide; this simplified the tooling and also the plumbing of the vessel. The propellants selected for both stages were NH3 and N2O4. Pressurization was to be achieved by heating the propellants to 145ºF and 232ºF respectively, an approach known as VaPak that had been developed by Aerojet in the early 1960s. Burt Rutan had used vapor pressurization in the N2O oxidizer tank for the hybrid engine of his SpaceShipOne. Using VaPak, the propellants would be raised to an initial pressure of 400 psi. As the tanks were emptied, the pressure would drop, allowing the hot propellants to boil and thus provide more pressurant gas. As propellants are expelled from pressurized tanks, their temperature will drop so that by the time all the liquids are drained from the tanks, pressure has fallen 20-30% from its original value. Approximately 7 to 10% of the propellants would be left in the vapor state after all the liquids are expelled. Vapor pressurization has some disadvantages - heating the propellants reduces their densities, and in order to achieve low propellant residuals (the leftover, unusable propellants), the engine must be operated for a time on the propellant vapors. However VaPak has many advantages. Residuals are low because, if one propellant's vapor pressure decays more rapidly than the other, the engine can still burn them; the mismatch in the relative amounts of each propellant results merely in a change in mixture ratio, rather than incomplete utilization of the propellants. Mixture ratio changes - while they do affect ISP - do not affect performance to the same extent that excessive residual propellants do. The vapor pressurization technique has the advantage of being completely automatic, i.e., no valves, regulators, or heat exchangers are required for it to work. In addition, the liquid propellants will tend to vaporize as they experience pressure drops while flowing through the feed lines or crossing the injector. This vaporization of the propellants improves mixing and results in high-efficiency with a simpler, less complicated injector design. Finally, because every drop in the pressure of the propellants causes additional vaporization, the propellant feed lines always contain some gas, which makes the propellants at all times compressible. Many rocket engines, especially in pressure-fed stages, have been plagued by combustion instabilities caused by an interaction between pressure oscillations in the thrust chamber; this is the well-known "pogo effect." A pressure oscillation in the engine increases the chamber pressure, which inhibits propellant flow into the engine, which in turn causes a decrease in chamber pressure, which in turn allows more propellants to flow into the engine, thus generating an even greater pressure pulse. The result is severe pogo-like vibrations which can destroy the vehicle. Some of the research done to eliminate pogo in the Saturn F1 engine showed it could be overcome by injecting a small amount of gaseous helium into the propellants (so as to make them compressible). The oscillations in the engine had relatively little effect on the flow of the now-compressible propellants; pressure waves are not as easily transmitted by compressible fluids. With the VaPak approach, a tank pressure of 400 psi could be used with a chamber pressure of 200 psi. Moreover an ISP of 215 seconds at sea level and 250 in vacuum appeared to be achievable with NH3 and N2O4. A 16-foot diameter tank with a nominal design pressure of 400 psi resulted in a tank wall thickness of 0.15 inches, which was thin enough to provide reasonable material toughness. The tanks could be designed with a safety factor of essentially 1.0; by using simple heating of the propellants for pressurization, you avoid the possibility of transitory overpressure in the tanks. Any increase in pressure would immediately cause some of the gas to condense, thus providing self-limiting pressure regulation. First stage tank weight was approximately 10% of that stage's total weight, or 90,000 pounds. With a vacuum ISP of 250 and an upper stage weight of 100,000 pounds, the first stage produced a vacuum equivalent delta V (change in velocity) of 13,400 fps. The upper stage tanks would weigh about 3,600 pounds, or between 3 and 4% of the weight of the fully loaded stage; total structure weight was approximately 6%, or 6,000 pounds. The upper stage, with a slightly higher ISP (280) and somewhat lower mass fraction, could place 10,000 pounds into low Earth orbit. The lower stage structure was estimated to cost $25 per pound and the upper stage structure $250 per pound. The cost of the propellants, NH3 and N2O4, would be about $0.50 per pound of propellant or $50 per pound of payload, giving a total cost for the vehicle of $425 per pound of payload. The Mass Production Concept Team 2 had deviated somewhat from the initial approach of taking an existing launch vehicle and reengineering it for commercial-type mass production. They ended up designing a single-stage expendable vehicle based on the Japanese LE-7 engine. This pump-fed engine, using LOX and LH2 at a mixture ratio of 6:1, has a sea level thrust of 250,000 lbs, a vacuum ISP of 440 seconds, and a very respectable thrust to weight ratio of nearly 65. This engine was flight-proven, having been used in the H-2A launch vehicle. Team 2's vehicle would not have quite the 10,000 pound payload capability which was the design target for each team. However, because it used an existing engine with good performance, Tom had allowed them to go ahead with this concept. Team 2 calculated that 12% of the weight of the vehicle would be injected into orbit. With reasonably efficient thrust structure and payload support system designs, this meant they could get approximately 3% of the launch weight for payload; for a 200,000 lb lift-off weight that meant 6,000 lb of payload. Quick inquiries with the Japanese - although going somewhat beyond the ground rules for this study - had indicated that they were quite willing to license the technology. Costing the LE-7 in mass-production mode, using comparisons with the highest production-rate jet engines, indicated that a rate of approximately 25 engines per day could bring the cost of the engine down to $250 per pound, or approximately $1 million per engine. The cost of the engine divided by the payload meant the engine contributed $166 per pound to the cost of launch. The lightweight aluminum tanks, at high production rates, were estimated to cost in the neighborhood of $20 per pound. The vehicle would have only about three pounds of structure per pound of payload, and so the cost of the structure of would be approximately $60 per pound placed into orbit. Thirty pounds of propellant per pound of payload, at a cost of 25 cents per lb would add $7.50 per pound of payload. Total cost should thus be about $250 per pound. Twenty-five vehicles per day would cost about $37,500,000 per day. Development cost seemed within the $3 billion capital budget. Thus, it appeared feasible to mass-produce a pump-fed, single-stage expendable vehicle with a cost of less than $250 per lb of payload to orbit. The Fully Reusable Vehicle Concept The third approach - a fully reusable launch vehicle - was necessarily limited to parametric studies, given the time available for this design exercise, and cost estimation. As Len Cormier of the Third Millennium Aerospace Company had argued persuasively some two decades earlier, the most important cost parameter for a reusable launch vehicle is its development cost. The cost of propellants for any reasonable two-stage launch vehicle, which should be able to place 1-2% of its launch weight into orbit as payload - for a wide range of commodity-type propellants such as liquid oxygen, hydrogen, kerosene, liquid propane, or liquid methane - is in the $5-10 per lb range. Plugging in a maximum development cost of $3 billion, an additional $2-5 billion for production start up, and providing for the necessity of producing over a hundred vehicles to get down the learning curve, so that for the 100th vehicle the average cost was approximately $200 million, the total cost of vehicle production would be about $28 billion for the first 100 vehicles. Assuming a payload capability on the low side at 5,000 pounds, and a targeted goal of $500 per lb, a total of 56 million pounds of payload (representing 11,200 flights) would then be required before the total payload weight launched times the cost per pound would equal the development and production costs. Obviously, when operating costs and the cost of money were added to this calculation, tens of thousands of flights would be necessary before the fully reusable vehicle would be economical. This was not really surprising, considering that for aircraft such as the Boeing 737 and 727, the number of flights per year for all airframes of a type exceeded one million. The results from the three studies were taken to the Group of Seven. After the presentations, the members certainly felt more educated and enlightened about the various approaches, and were genuinely encouraged that all of the approaches were shown to be workable options in pursuit of the low-cost spaceflight objective. However, Forsyth proceeded to throw some cold water on their enthusiasm.

"This is nonsense," he said. "Here we are talking about tens of flights

per day, when the worldwide market for launch vehicles in this size

range is much less than a hundred per year, and two-thirds of those

payloads wouldn't look at our vehicle even if it were free! I may have

a billion dollars to spend, and between us we could spend three to five

billion, but that's clearly not enough to build any of these systems

if it's going to take $5-10 billion dollars per year in launches to

achieve our cost goal. There aren't nearly enough customers with enough

payloads to come close to paying us for all that launch capacity. Now

it might be that if some government wanted to mass produce a vehicle,

spending $5-10 billion per year, eventually some new uses, some new

demand, might arise for low-cost space launch. But gentlemen, we are

not a government and, frankly, I don't think that building and throwing

away 10, 20 or 30 launch vehicles a day is ever going to produce the

paradigm shift we want. There must be another approach. There must be

some way we can start small - our three billion is small compared to

these numbers - and make something that will allow us to grow the market

for low-cost space transportation. We have to actually make some money,

not just burn it! We'll have to make money if we hope to get access

to the capital market to fund the full-blown opening of the frontier."

|

|||||

|

|||||